PCSpecialist responds to our Element Elite R article

Yesterday we published an article and accompanying video, detailing the Element Elite R prebuilt PC that we were sent by PCSpecialist. We demonstrated how the system had been built improperly, resulting in the PCIe riser cable completely blocking one of the two AIO cooler fans. We reached out to PCSpecialist with our findings and questions and have today received a full response.

If you haven't already, be sure to check out on the original article and video which explored everything in detail, and the issues raised by our findings. We had already reached out to PCSpecialist before publishing to let them know what we had found, inviting a response to our article. Dialogue opened yesterday and today we were sent a full statement from the company.

First and foremost, it was good to see the company took responsibility for the issue, with a statement from John Medley, PCSpecialist Head of Sales & Marketing, agreeing that the issue shown ‘should not have happened' and was clearly ‘short of the high standards we hold ourselves to and that our customers rightly expect from us.'

The statement also gave additional context to the build error. According to Medley, TR100 builds are a recent addition to PCSpecialist configurators and the number of systems using the case ‘to date is very small, they represent just 0.08% of orders since it was introduced'. Furthermore, most of those builds were configured with a low-profile air cooler – specifically the be quiet! Pure Rock LP – so even fewer use an AIO with this case. On top of that, the statement says PCSpecialist reviewed the database of customer orders and found ‘that there are no customer orders built into the TR100 at risk of potentially overheating'.

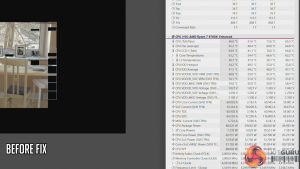

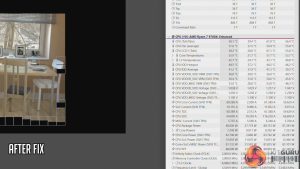

Images above provided by PCSpecialist.

To illustrate the point, we were also provided with the above images from PCSpecialist's build preview tool, showing proper routing of the PCIe riser cable for these systems built into the TR100 chassis.

As to how this managed to happen in the first place, Medley told us that PCSpecialist's standard process ‘includes both a visual inspection and functional stress tests. In this instance, the bracket/stuck fan was not caught at either stage. We are reviewing why that was the case and updating our processes to ensure case-specific requirements are explicitly signed off before any system is dispatched. This will apply to all new chassis going forward.'

On top of that, PCSpecialist emphasised that ‘retrospective training has already begun to further improve the quality of our builds', and while the company acknowledged that mistakes can happen as each system is hand-built, Medley said that PCSpecialist is using this as ‘an opportunity to strengthen our processes, improve our training, and to continue developing our skilled team.'

Lastly, PCSpecialist emphasised the importance of ‘independent scrutiny' and rightly pointed out that the vast majority of prebuilt PCs that we have reviewed from them in the past, have been positively received. In closing, Medley told us the following: ‘We have listened, we have taken the feedback onboard, and we can assure your readers that action has been taken to improve even more moving forwards.'

KitGuru says: Thanks to PCSpecialist for providing with us with such a detailed response. While we would have liked to avoid this situation in the first place, the company certainly seems to be taking the matter seriously and improving its processes as a result.

—

For transparency, the full statement provided to us by John Medley is copied below:

First and foremost, the build error identified in your review should not have happened. The bracket was not correctly utilised, and this clearly falls short of the high standards we hold ourselves to and that our customers rightly expect from us.

We also want to acknowledge the value of independent scrutiny of this kind. Honest reviews give your audience confidence that coverage is not influenced by the brands being reviewed.

Addressing your questions:

We cannot publicly share exact sales data, but we want to provide context. The TR100 has only recently been added to our configurators and units built to date is very small, they represent just 0.08% of orders since it was introduced. The majority of those have been configured with a low-profile air CPU cooler (be quiet! Pure Rock LP), meaning the pool of TR100 builds with a 240mm AIO is smaller still. Whilst not utilising the bracket correctly is the primary issue; our immediate focus has been on TR100 + 240mm AIO builds, specifically where the potential impact could be more severe.

The automated photography of each customer build has been referenced in the article, video, and comments. To clarify, this process is fully automated so the images are not taken or edited by a staff member, and they are captured without power, meaning fans don’t spin and lighting will not be illuminated.

In reviewing the database of customer order images potentially impacted by this issue, we are pleased to confirm that there are no customer orders built into the TR100 at risk of potentially overheating. Things to keep in mind:

- The TR100 is a niche product with low sales volume, so the pool of potentially impacted sales was very small.

- The majority of TR100 system orders have been ordered with a be quiet! Pure Rock LP cooler, which does not have a radiator or top mounted fans.

- We have dozens of system builders within our team, thankfully most have followed the correct process and are utilising the bracket correctly.

Our standard build and QC process includes both a visual inspection and functional stress tests. In this instance, the bracket/stuck fan was not caught at either stage. We are reviewing why that was the case and updating our processes to ensure case-specific requirements are explicitly signed off before any system is dispatched. This will apply to all new chassis going forward.

Each order is tracked throughout production, and every stage is logged by a staff member. This has allowed us to trace each order back through the production process and retrospective training has already begun to further improve the quality of our builds. All systems are assembled by hand, and unfortunately by nature humans can make mistakes. We are taking this as an opportunity to strengthen our processes, improve our training, and to continue developing our skilled team.

Between Jan 2020 – Jan 2026, PCSpecialist has submitted 28 systems to Kitguru’s editorial team for an unbiased and honest review, the average score of these systems is 8.19/10 and we’re confident if we went back to further the average score would remain high.

Over the past 10 to 15 years, our systems have received high acclaim from Kitguru, many have been accredited awards, and even EHA (European Hardware Association) recognition. PCSpecialist are incredibly proud of the quality standards we have achieved on a consistent basis over two decades of trading. We do not send golden samples to the press like many companies within our industry do. All sample units come directly from our production line with no additional intervention or checks, because like you, we want reviews to be a true reflection of what our customers receive.

The Element Elite R is the first system KitGuru have received to fall short of the high standards we expect of ourselves and we acknowledge this. We have listened, we have taken the feedback onboard, and we can assure your readers that action has been taken to improve even more moving forwards.

The post PCSpecialist responds to our Element Elite R article first appeared on KitGuru.